CenterMax® Band Screens

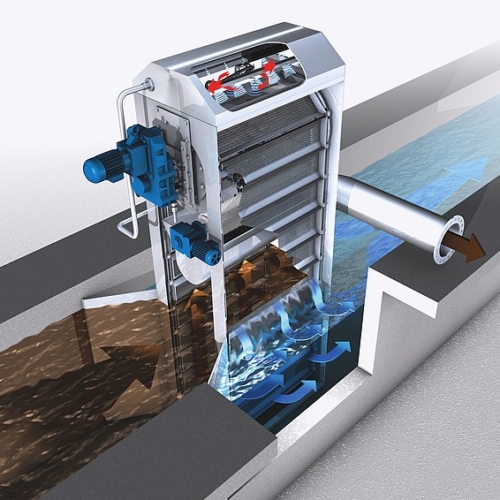

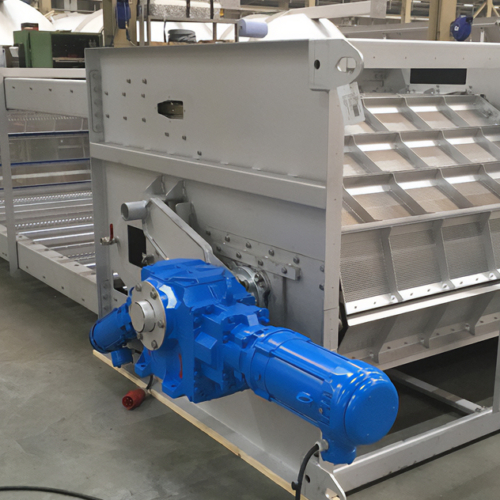

The CenterMax® is a high efficiency, centre flow band screen used in the headworks of a sewage treatment plant.

High efficiency fine screening from a sewage treatment plant’s inlet significantly reduces maintenance costs from blockages due to screenings accumulation within the aeration and sludge processing plants.

- High efficiency screening – 80% Capture Ratio

- Reduced maintenance costs on downstream processes

- Heavy duty stainless steel panels

- Side seals and interpanel seal stops any bypass

- 20 years of sizing and design expertise specifically for Australian applications

CenterMax® Band Screen uses a continuous band of perforated panels that provide high efficiency two dimensional screening. Rags, fine screenings, plastics, bags and other foreign objects are captured on the panel face and removed from the sewage flow via a water jet and rotating brush arrangement. The band also includes a series of serrated wipers to remove larger objects such as cans and small plastic bottles.

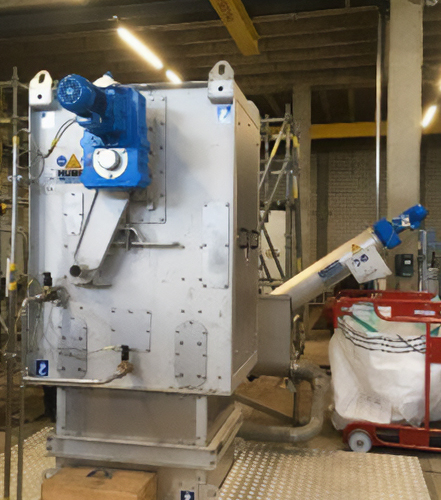

Hydroflux Epco provides complete inlet works systems, including screening removal and handling, grit removal and handling, as well as any associated conveying systems. We provide comprehensive technical analysis for hydraulics, headloss, screen control and solids conveying systems providing with a packaged solution to meet their needs.

Find out more

A CenterMax® Band Screen comprises the following features:

- Highest screenings efficiency – double the efficiency of bar and step type screens

- A high flow capacity due to centre flow profile

- Fully automatic operation

- Heavy duty design with the panels attached to a roller chain

- Panels are available in stainless steel and in a range of apertures

- No submerged sprockets or bearings

- Automatic bypass

- A standard size range to suit new and existing installations

CenterMax® is a center flow band screen used for removing coarse and fine material from sewage and wastewater. A summary of the description of operation is as follows:

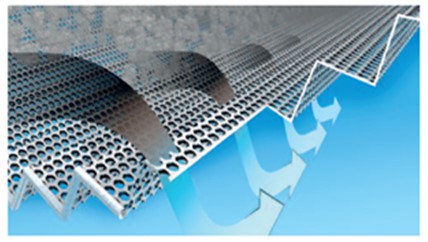

- The screen uses a perforated plate band that is mounted on chain system, aligned ninety degrees in the direction flow.

- As screenings accumulate on the perforated panels, the headlosss through screen rises; this headloss is used to initiate a screen clean in addition to

timer control. - The perforated plates are connected with a drive chain on both sides driven by chain wheels. Each chain is driven by a pinion on a common shaft and a flange gearbox above the channel.

- Seal fins are mounted on the side each of the plates and a further seal between the plates to prevent screenings bypass.

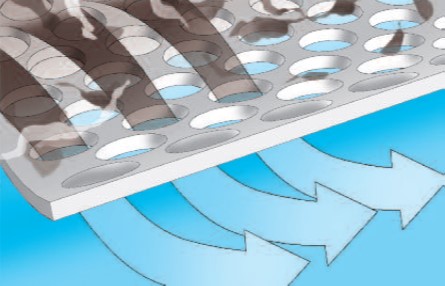

- In the upper drive section of the screen above the channel, the perforated plates are cleaned by a rotating brush from the inside. In addition the plates are washed from outside to inside via a spray jets mounted to a spray bar which is located downstream of the rotating brush.

- The sluiced screenings flow by gravity through an internal launder channel to the next treatment stage. To ensure the screenings are reliably transported, additional flush water is required, e.g. screened wastewater from downstream of the screen.

- The two-dimensional perforated elements prevent especially long fibres from passing through the screen and achieve thus the maximum separation efficiency.

- For the reliable removal of the material contained in the wastewater, tines are mounted over the full length of the filter elements to ensure forced delivery of the material to the upper discharge point.

- Chain guide discs are mounted in the bottom section of the screen. No moving parts of the screen are submerged in the water.

- Municipal sewage (raw)

- Municipal sewage (pre-MBR)

- Municipal RAS screening

- Industrial applications

CenterMax® is available in four different inlet widths and with variable panel lengths to accommodate a wide range of flow rates, channel configurations and water levels. Capacities range from 200 through to 3500 L/s in a single screen.

CenterMax® is selected to ensure a velocity profile through the centre feed section, perforated panels and discharge result in a headloss between 200 and 500mm.