Sludge Acceptance Plant

HUBER Sludge Acceptance Plant RotaShield®

The HUBER Sludge Acceptance Plant RotaShield® is an advanced septage receiving system designed to efficiently handle high solids throughput. It features a rotating high-performance screening drum that ensures reliable, clog-free solids transport through guided material movement within the drum.

This design allows for rapid emptying of tanker vehicles, reducing unloading times to under seven minutes per truck. The RotaShield also offers defined separation sizes due to its two-dimensional screening, operates within a fully enclosed unit to prevent odour issues, and requires minimal maintenance due to its robust construction.

During operation, wash water is introduced to pre-wash and homogenise the raw material. The perforated plate of the wash drum retains particles larger than the perforation, which are then dewatered and discharged into a skip.

As only coarse material is separated based on the perforation size, the volume of residual waste is significantly reduced. The remaining mineral material is generally further processed in the downstream HUBER Coanda Grit Washer RoSF4. Additionally, the coarse material can be further classified into mineral and organic fractions using a coarse material washer.

Features and Benefits of the RotaShield

The RotaShield is a robust and efficient screening system designed for high solids throughput, offering reliable performance even with challenging materials while ensuring optimal hydraulic capacity and minimal maintenance requirements.

- High solids throughput even with problematic material (wet wipes, grease, stones)

- High hydraulic capacity even with high solids contents

- Defined separation size due to two-dimensional screening

- Feeding from a conveyor, through a launder channel or pressure line

- Solids throughput up to 6 m³/h

- Completely encased unit

- Insensitive to coarse material

- 3 to 100 mm separation size

- Screened wastewater can be used as washwater

- Short tanker vehicle emptying times

- Optional simultaneous emptying of several vehicles

- Minimum wear, reduced maintenance

- Compact, space-saving design

- Low energy demand

- High corrosion resistance

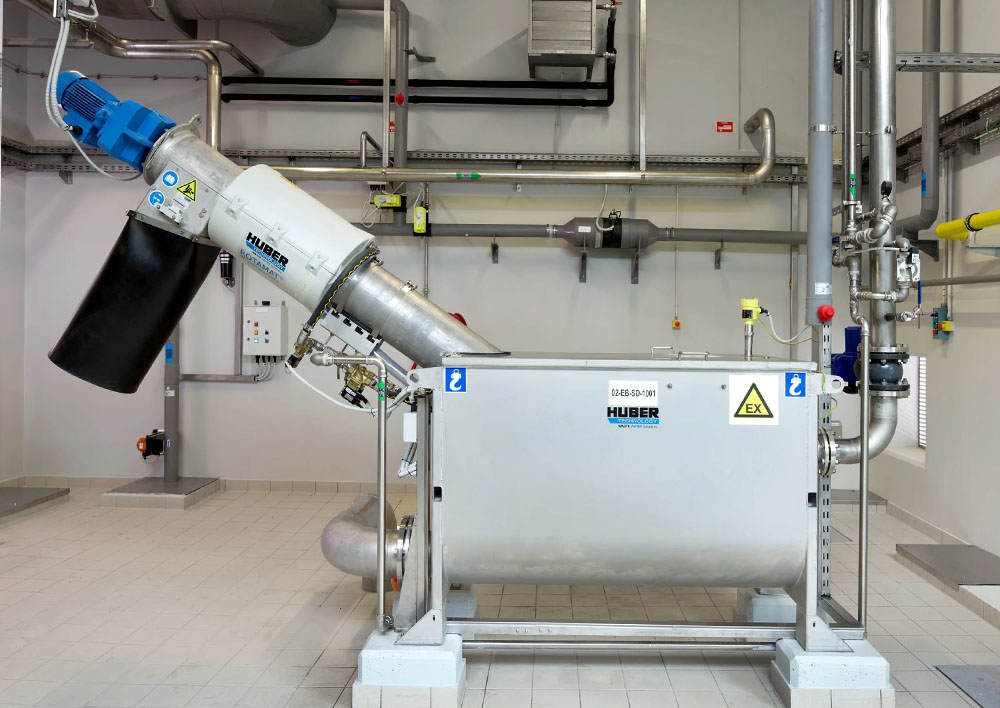

HUBER Sludge Acceptance Plant ROTAMAT® Ro3.1

The HUBER Sludge Acceptance Plant ROTAMAT Ro3.1 is a robust and highly efficient system, widely regarded as the most reliable solution of its kind. Its advanced design ensures dependable operation, year after year. For installations in colder environments, a heated and insulated version is available as an option.

At the core of the Ro3.1 system is the proven HUBER Fine Screen ROTAMAT Ro1, which offers high throughput, excellent separation efficiency, and minimal head loss. Floating and suspended materials are effectively retained within the screen basket, while an integrated screenings press enhances solids handling and reduces disposal volume.

Designed for durability, the ROTAMAT Fine Screen is constructed entirely from stainless steel and is built to withstand demanding conditions, including exposure to rocks and grit. Its self-cleaning mechanism ensures reliable operation, with rake tines fully engaging the basket bars for continuous, clog-free screening.

Sludge Acceptance Plant with Grit Trap and Grit Classifier – ROTAMAT Ro3.3

The HUBER Sludge Acceptance Plant ROTAMAT Ro3.3 is designed for the complete separation of screenings and grit, ensuring reliable and efficient removal of disruptive materials from all types of septic sludge. Its robust and dependable operation makes it an ideal solution for sludge reception facilities.

Fine screen with integrated screenings press – Effectively retains and compacts solids for easy disposal.

Unaerated grit trap with integrated grit classifier – Ensures thorough separation of grit and heavy particles.

By integrating all components into a single tank, the system maintains a compact footprint while minimising odour emissions. The complete treatment process occurs within a single unit, enhancing efficiency and simplifying operation.

From Concept to Completion – Contact Hydroflux Epco for Tailored Sludge Acceptance Plant Solutions

Effective screening and grit separation are essential for effectively controlling septic sludge. Hydroflux Epco provides customised solutions, working closely with clients to develop efficient designs for new projects or ones that integrate seamlessly into existing facilities.

Our expert team delivers comprehensive design documentation and ensures optimal handling, storage, and disposal of removed material for compliance and efficiency. With deep technical expertise, we guide clients in selecting and optimising the right systems for their needs.

Contact Hydroflux Epco today to learn how our high-performance solutions can streamline your operations.

HUBER Sludge Acceptance Plant Brochures

Please download the HUBER Sludge Acceptance Plant brochures here.