Containerised Sludge Dewatering

HySludge® – Reliable Sludge Dewatering or Thickening for Remote and Off-Grid Applications

Managing sludge from wastewater treatment plants in decentralised and remote areas presents significant operational and cost challenges, particularly due to limited disposal options and the high expense of transporting liquid sludge. HySludge® by Hydroflux Epco delivers a plug-and-play, containerised sludge dewatering or thickening system designed for reliable and efficient performance in even the most challenging locations.

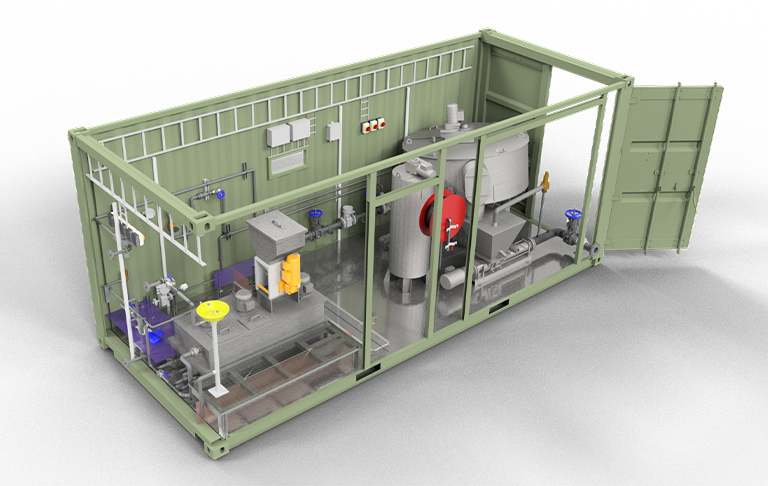

Each HySludge unit is housed in a modified 20-foot high cube shipping container and is delivered to site wired, preassembled, and factory tested. Onsite installation works are minimal with most components already installed, including the dewatering or thickening unit, conveyors, pumps, pipework, controls and dosing system. Just connect power, air, and process lines, and the system is ready to operate. It is a true Packaged Sludge Dewatering solution built for fast deployment and simple integration.

Ideal for municipal and industrial applications, HySludge drastically reduces sludge volumes while simplifying operation and maintenance, making it the ideal choice for sites with limited infrastructure or operator access.

Key Benefits with Flexible Configuration Options

HySludge systems are tailored to meet your site’s specific sludge treatment requirements:

Fully Customisable Container – Layout and features are designed for your operational needs. Preassembled, factory tested and ready to operate.

Efficient Dewatering or Thickening – Low energy use with the HUBER Q-PRESS® available in multiple sizes or the HUBER S-DISC, depending on your needs.

Material Options – All process equipment available in either 304 or 316 stainless steel.

Minimal Installation – Simple site connection reduces installation time and cost.

Compact and Portable – All fits within a standard high cube container footprint.

Control & Automation – Integrated PLC and HMI within control panel constructed to AS Standard.

HySludge Typical Scope of Supply

HUBER Q-PRESS® Screw Press or S-DISC® Thickener, with polymer injection ring, mixing valve and static mixer.

Optional Screw Conveyor: HUBER Ro8T, variable length depending on discharge, stainless steel, with supports and discharge chute.

Polymer Dosing System: inline preparation and dosing system.

Interconnecting Pipework: PVC piping with flanged terminations for sludge, washwater, and filtrate.

Air Compressor: Supplied if required or compatible with site air supply.

Sludge Feed Pump: Helical rotor positive displacement pump (or option to connect to site feed).

Control System: Hydroflux standard – full skid wiring, PLC, and HMI.

Modified Shipping Container: 20 ft high cube, internally fitted for safe and efficient operation.

Contact Hydroflux Epco for an initial technical discussion

Hydroflux Epco combines deep process knowledge with market-leading equipment to deliver robust, practical sludge handling solutions. With decades of experience across Australia and the Pacific, we’re the trusted partner for reliable decentralised wastewater treatment.

Get in touch with Hydroflux Epco today to explore how a HySludge® system can be tailored to meet your site’s requirements.