Moving Bed Biofilm Reactor (MBBR)

Moving Bed Biofilm Reactor (MBBR) Systems for Municipal Applications

Moving Bed Biofilm Reactor (MBBR) systems offer a highly efficient and scalable solution for municipal wastewater treatment. With increasing population densities and tightening environmental regulations, municipalities require advanced treatment technologies that enhance treatment performance while minimising operational complexity. Hydroflux Epco’s MBBR systems provide a robust and cost-effective alternative to conventional biological treatment methods.

Why Choose MBBR for Municipal Wastewater Treatment?

MBBR technology utilises free-moving biofilm carriers within an aeration tank to enhance biological treatment efficiency. This process provides significant advantages for municipal wastewater treatment, including:

High Treatment Efficiency – MBBR technology supports a high biomass concentration, improving organic matter and nutrient removal.

Compact Design – Requires less space than conventional activated sludge systems, making it suitable for municipalities with limited land availability.

Process Stability – The attached biofilm process ensures resilience against hydraulic and organic load variations, reducing system disruptions.

Low Sludge Production – Compared to traditional processes, MBBR generates less excess sludge, lowering sludge handling and disposal costs.

Reduced Operational Complexity – MBBR systems do not require sludge recycling, simplifying plant operation and maintenance.

Upgrading Conventional Activated Sludge Systems to MBBR

Municipalities with existing conventional activated sludge (CAS) treatment plants can easily upgrade to MBBR technology without extensive modifications. The upgrade process involves:

Retrofitting Biofilm Carriers – Existing aeration tanks can be converted into MBBR reactors by introducing biofilm carriers, eliminating the need for additional tank construction.

Aeration System Optimisation – Minor modifications to the aeration system ensure optimal carrier movement and oxygen transfer efficiency.

Improved Treatment Performance – Upgrading to MBBR enhances nutrient removal capabilities, allowing municipalities to meet stricter discharge limits.

Capacity Expansion – MBBR technology enables existing treatment plants to handle higher loads without increasing their footprint, making it an ideal solution for growing communities.

Hydroflux Epco’s Expertise in MBBR Solutions

Hydroflux Epco designs and supplies high-performance MBBR systems tailored for municipal wastewater treatment. Our expertise includes:

Customised MBBR Designs – We optimise treatment configurations based on influent characteristics, effluent requirements, and plant constraints.

Modular and Scalable Solutions – Our MBBR systems can be easily expanded to accommodate future population growth.

Advanced Process Control – Automation and monitoring systems enhance performance and reduce energy consumption.

Local Support and Spare Parts – With a strong network of service teams and readily available spare parts, we ensure long-term system reliability.

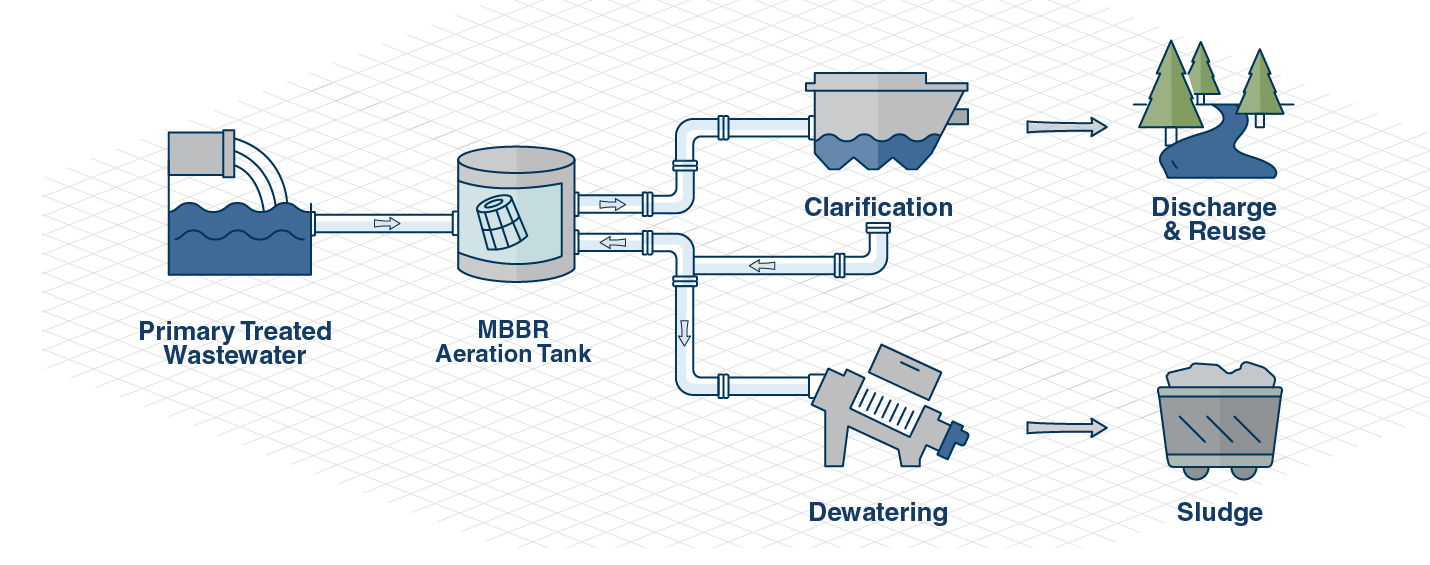

How the MBBR Process Works

MBBR is an aerobic biological treatment process where microorganisms attached to suspended carriers degrade organic pollutants in the presence of oxygen. Unlike suspended growth systems, MBBR supports a dense population of biomass on specially designed carriers, allowing higher treatment capacity in smaller tanks.

The Stages of the MBBR Process

- Influent Introduction: Raw or partially treated wastewater flows into the MBBR aeration tank at a steady rate.

- Biological Treatment: Within the aeration tank, specially designed plastic carrier elements move freely, providing a large surface area for biofilm growth. Oxygen is introduced via fine-bubble aeration to support aerobic biological activity. Microorganisms on the carrier surfaces degrade organic pollutants and nutrients in the wastewater.

- Solid-Liquid Separation: After biological treatment, the mixed liquor flows to a downstream clarification system, typically a secondary clarifier, where biofilm fragments and suspended solids are separated from the treated water.

- Effluent Discharge: Clarified effluent is either discharged or undergoes further polishing, depending on final discharge requirements.

- Sludge Handling: Excess biomass (waste-activated sludge) from the clarifier is removed for dewatering and disposal. In some configurations, a portion of the settled sludge may be returned to the aeration tank, depending on the plant design.

MBBR Components

High-quality MBBR Carriers with a high surface area are critical to the performance

Carrier design is critical to system performance. Hydroflux Epco uses high-surface-area, open-structured carriers manufactured from durable, recycled PE. These injection-moulded elements resist clogging and maximise biofilm growth and mass transfer efficiency.

High-quality and efficient aeration grids that utilise the entire tank surface area

Our aeration grids cover the entire tank floor to ensure uniform oxygen distribution and efficient mixing. Designed to be clog-free and low-maintenance, these systems are highly prefabricated to reduce installation time and maintain consistent quality.

Standard ancillaries

Hydroflux Epco offers robust media retention cages to securely contain MBBR carriers within the aeration tank. These are designed to optimise flow dynamics and ensure effective treatment while preventing fouling or loss of media.

Foaming in aeration tanks can disrupt performance. Hydroflux Epco can provide automated and semi-automated foam control solutions, tailored to each site based on years of operational experience.

Contact Hydroflux Epco to Discuss How MBBR Can Benefit Your Site

Looking to upgrade your wastewater treatment plant or design a new system with advanced MBBR technology? Hydroflux Epco works closely with municipalities, consultants, and contractors to deliver turnkey solutions that maximise performance and long-term reliability.

Get in touch today to discuss your MBBR project.