Solar Sludge Drying

Solar Sludge Drying with the HUBER SRT System

The HUBER Solar Sludge Drying technology offers an innovative and sustainable solution for sludge management by harnessing the power of the sun. In the Australian climate, with its abundant sunshine and favourable conditions, solar drying presents a highly efficient and cost-effective approach to reducing sludge volume while minimising environmental impact.

Hydroflux Epco, a leader in wastewater and sludge treatment solutions across Australia, partners with HUBER to deliver advanced solar drying systems tailored to the unique needs of local councils, water utilities, and industrial facilities.

Dewatered sludge to be dried is spread out on the floor inside a greenhouse structure. What makes the HUBER SRT system special is the HUBER Sludge Turner SOLSTICE®, which performs spreading and granulation of the sludge in the greenhouse and aeration, turning and mixing of the sludge bed.

Features and Benefits

What are the reasons to choose the HUBER SRT Solar Sludge Drying System?

- Significant reduction in disposal costs by harnessing free solar energy

- Production of homogeneous, stable, and dry sludge suitable for various applications

- Long-lasting performance ensured by robust, low-maintenance machine technology

- Effective handling of challenging sludge types through advanced sludge bed management

- Low operating costs, delivering long-term savings in disposal expenses

Operation

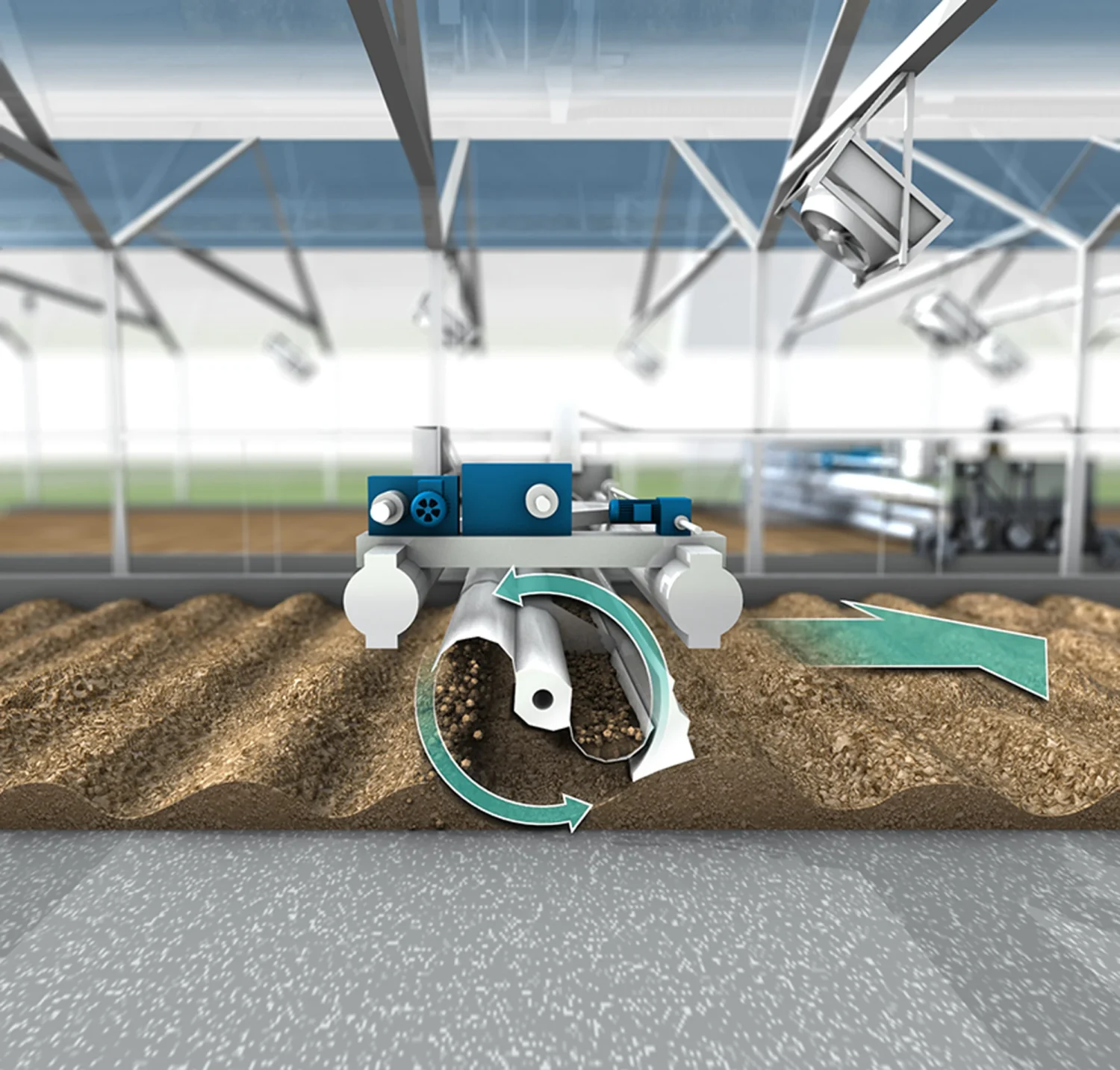

What makes the HUBER SRT system special is the HUBER Sludge Turner SOLSTICE®, which performs spreading and granulation of the sludge in the greenhouse while also aerating, turning, and mixing the sludge bed. The HUBER Sludge Turner SOLSTICE® is equipped with two motors: one motor drives the machine longitudinally across the drying area, while the second motor rotates the double shovel during forward travel to tip the sludge over its axis back into the sludge bed.

The intensive mixing of the sludge minimises odour-producing processes, enhancing the drying process. This consistent agitation ensures that the sludge is evenly exposed to sunlight and airflow, optimising moisture evaporation. The rotary motion inside the shovel forms round and mechanically stable granules, which are easier to handle and transport. This granulation process not only stabilises the sludge but also contributes to its suitability for various reuse applications.

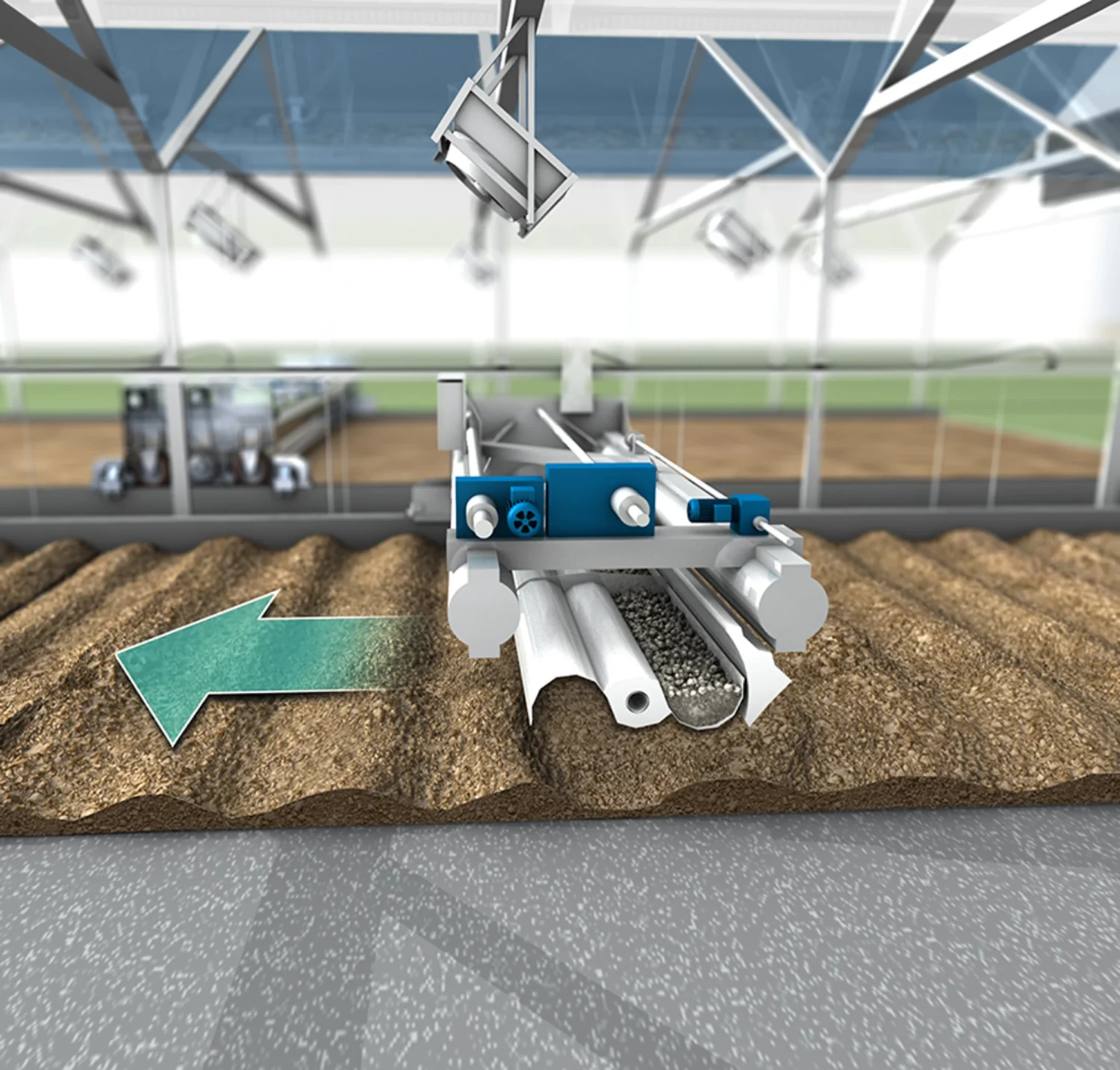

As the machine travels from one end of the greenhouse to the other, the rotating double shovel ensures the sludge is completely restacked, promoting even drying and consistent results across the entire sludge bed.

The HUBER Sludge Turner SOLSTICE® can optionally use its double shovel to transport dried sludge. The machine can transport dry sludge back to the sludge feeding area and mix it into the freshly dewatered sludge, providing several key advantages. Backmixing of dry sludge reduces odour-generating biological processes within the sludge due to the reduced water content and by lowering the moisture content, microbial activity that produces unpleasant odours is significantly minimised. The addition of dry sludge also makes pasty sludge easier to handle..

Moreover, the drying process is accelerated. Dry sludge introduces an open-porous structure that increases the surface area available for moisture evaporation, resulting in quicker and more effective drying.

The machine can be optionally equipped with a blade that adjusts to the level of the sludge bed during sludge turning. A motor raises or lowers the blade depending on the measured sludge bed level. As larger sludge lumps are processed, they are cut into smaller pieces between the rotating shovel and the blade. This precise control ensures a consistent sludge bed height and optimised dry residue levels throughout the drying process.

Contact Hydroflux Epco for an initial technical discussion

Sludge drying is becoming an increasingly important aspect of wastewater treatment as municipalities and councils seek more efficient and sustainable methods for managing waste. Hydroflux Epco, with its extensive expertise and technical know-how, is at the forefront of this shift, offering advanced sludge drying solutions tailored to meet evolving industry demands.

Our team of experts understands the complexities of sludge drying processes and is equipped to provide in-depth guidance and customised solutions. With years of experience and a proven track record, Hydroflux Epco can initiate meaningful discussions about the benefits and requirements of sludge drying for various applications.

Get in touch with Hydroflux Epco today to find out how we can help streamline your sludge drying process.