Raw Water Intake Screens

Advanced Raw Water Intake Screening Solutions

Hydroflux Epco offer a wide range of Rotary Drum Filter and Dual Flow Basket Filter solutions from Flootech. Both systems treat various water sources for use in cooling towers, municipal desalination plants and industrial process water make-up.

The screening solutions can be used for fresh and seawater intakes. With installations dating back to the 1960s, Flootech’s Rotary Drum Filters are industry proven, robust and can be combined with Dual Flow Basket Filters to provide complete intake solutions with very high filtration grades (35 – 50 microns).

Applications

Stormwater and Combined Sewer Overflow (CSO) Control

Prevents solids and debris from entering natural water bodies during storm events, ensuring compliance with environmental regulations.

Retention Tank and Wastewater Treatment Plant Protection

Retains solids at overflow points, reducing pollutant loads and improving treatment efficiency.

Urban and Industrial Drainage Systems

Enhances stormwater management in municipal and industrial settings by intercepting solids before discharge.

Refurbishment of Existing Infrastructure

Easily integrated into existing overflow weirs and retention systems to improve solids separation without major modifications.

Benefits

High Solids Retention & Low Hydraulic Resistance

Efficient two-dimensional screening captures solids while allowing high flow rates with minimal headloss.

Automatic Self-Cleaning & Low Maintenance

Integrated brush and screw mechanism ensures continuous cleaning, reducing manual intervention and maintenance.

Flexible & Reliable Operation

Can be installed on either side of the overflow weir and operates efficiently even at low flow rates without blockages.

Durable & Environmentally Friendly

Robust stainless steel construction ensures long-term reliability while preventing pollution in receiving waters.

Flootech Dual Flow Basket Filters

Flootech Dual Flow Basket Filters are specifically designed for preliminary filtration and gross solids removal, effectively filtering particles as small as 0.2 mm. Water enters the main feed channel, flowing continuously through the centre of the screen and out both sides of the travelling baskets (dual flow), where it is filtered by the mesh sieve within the baskets.

As material accumulates in the baskets, the differential pressure across the screen increases, gradually lowering the downstream water level. A level sensor continuously monitors the water levels upstream and downstream. Once the downstream level falls below a set point, the PLC control system triggers a wash cycle.

During the wash cycle, the screen rotates while a series of wash jets direct accumulated debris into a central launder for collection and disposal. The clean screen surface then returns to the feed channel, and the wash cycle continues until the downstream water level stabilises.

Flootech Dual Flow Basket Filters offer several advantages over traditional intake screens. A key benefit is their ability to handle variable water levels, making them particularly well-suited for seawater intake systems. Additionally, they provide superior filtration performance compared to conventional intake screening solutions, achieving filtration down to 0.2 mm.

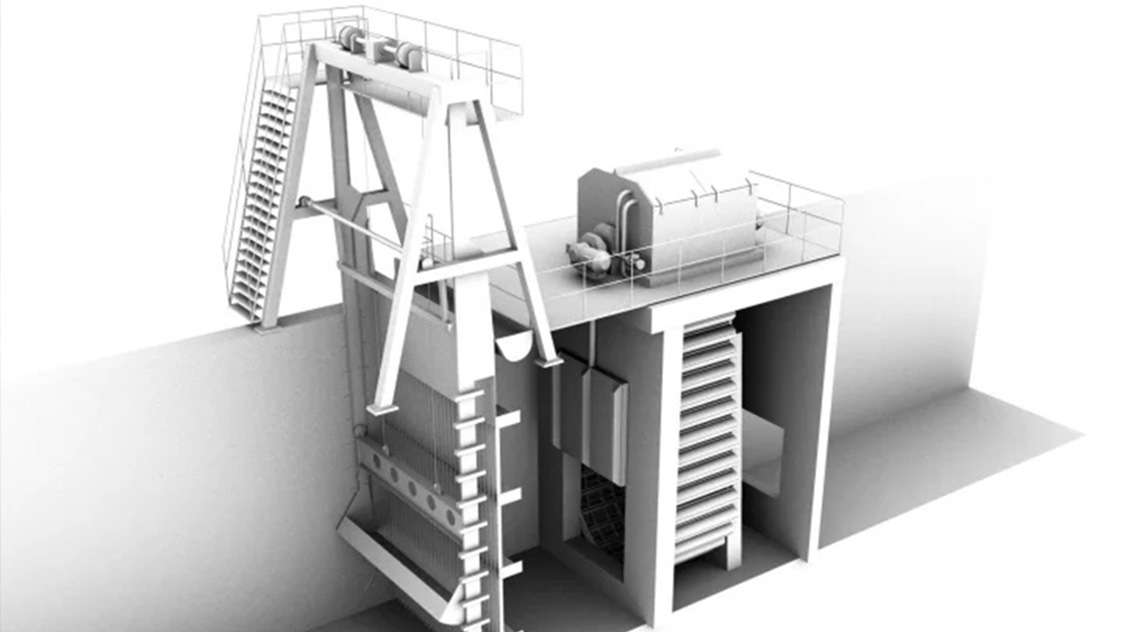

Advanced Rotary Drum Filtration Solutions for Efficient Water Treatment

In partnership with Flootech, Hydroflux Epco offers a comprehensive range of Rotary Drum Filter solutions for treating various water sources in large-scale cooling towers, municipal desalination plants, and industrial process water make-up systems. These screening solutions are suitable for both freshwater and seawater intakes. With installations dating back to the 1960s, Flootech’s dual-flow basket screens are industry-proven, robust, and deliver a significantly lower total cost of ownership compared to traditional drum filters.

The Flootech Rotary Drum Basket Filters are designed for preliminary filtration and gross solids removal, filtering particles as small as 35 microns. Water enters the holding tank through the centre of the drum, passes through the filter to the outside, and then flows over a weir within the holding tank before being discharged.

The washing cycle, controlled by a timer, typically operates for 10% of the total runtime. External wash jets clean the filter, directing debris into the central collector for disposal via the discharge pipe. The clean screen surface then returns to the feed channel, and the wash cycle continues until the downstream water level stabilises.

Flootech Rotary Drum Filters offer several advantages over traditional drum screens, including a high surface area relative to the installed tank volume (m²/m³), made possible by the drum’s unique design. This results in significant capital and operational cost savings compared to conventional technologies.

For enhanced performance, Flootech Rotary Drum Filters can be combined with Dual Flow Basket Filters to create complete intake solutions with high filtration grades ranging from 35 to 50 microns.

Contact Hydroflux Epco for an Initial Technical Discussion

Screening is a critical component of wastewater treatment, ensuring the efficient removal of solids to protect downstream processes and improve overall plant performance. Hydroflux Epco, with its extensive expertise and technical know-how, offers a comprehensive range of screening solutions designed to meet the needs of any municipality.

Our team of experts understands the complexities of screening processes and will always provide tailored advice on selecting, designing, and optimising the correct screening systems in each case.

Get in touch with Hydroflux Epco today to learn how we can help streamline your wastewater treatment operations with reliable, high-performance screening solutions.