Sludge Dewatering

The Best Choice for Sludge Dewatering at Municipal STPs

The HUBER Q-PRESS® Inclined Screw Press is a proven, high-performance sludge dewatering solution, developed by HUBER over 20 years ago and installed in over 1,200 applications worldwide. Several HUBER Q-PRESS models are available with capacities ranging from 20 to 540 kg DS per hour to suit virtually any municipal application.

This advanced screw press technology has become the preferred choice for many Water Authorities globally, including in Australia. It delivers comparable dewatering performance to traditional decanter centrifuges while consuming just 10% of the energy. This results in significant cost savings on power consumption reduces offsite truck movements and lowers operational costs.

With decades of experience in sludge dewatering, Hydroflux Epco has successfully delivered and integrated HUBER Q-PRESS® solutions across numerous municipal and industrial treatment plants. Our expertise ensures that each system is tailored to site-specific needs, providing optimised performance, energy efficiency, and long-term reliability. Explore HUBER Q-PRESS installations at STPs across Australia in the gallery below.

Features and Benefits

- Comparable cake solids to centrifuges: High volume reduction leads to lower sludge transport and disposal costs.

- Energy-efficient operation: Consumes less than 10% of the energy required by centrifuges, using Super Premium IE4 motors.

- High dewatering performance: Achieves 18-25% DS, with up to 97% sludge volume reduction in a single step.

- Low-speed operation: Maximum internal screw speed of 1 rpm for gentle sludge handling.

- Minimal water usage: Very low intermittent washing demand with a segmented spray bar system.

- Triple-stage internal basket: Includes feed, middle, and pressure zones for optimal dewatering.

- Split-basket option: Enables in-situ overhaul without dismantling the main screw.

- Automated operation: Screw speed control automatically adjusts to feed solid variations.

- Fully enclosed design: Prevents odour and aerosol emissions, ensuring WHS compliance.

- Continuous dewatering process: Allows external cleaning of the filter basket without interrupting operation.

- Proven technology: With 1,000+ global references, it is effective for aerobic, anaerobic, THP, and industrial sludges.

Smart and Simple Design for Smooth Operation

The HUBER Q-PRESS® consists of a main case, internal screw rotating at <1.5 rpm, spray bar, and cylindrical wedge wire/mesh drum. Sludge enters the unit and is conveyed by the screw through the drum, while filtrate drains through the mesh. The drum consists of variable apertures and profiles, and together with a reduced screw pitch and increased shaft diameter, pressure is gradually applied as the sludge moves up the drum.

An adjustable pneumatic cone at the outlet optimises pressure to achieve maximum sludge dryness. A unique scraper system continuously cleans the inner filter surface, enhancing dewatering efficiency and reducing polymer consumption.

The inclined design ensures that filtrate discharge benefits from gravity assistance, further improving efficiency.

The cake is discharged through the cone into a bin or conveyor system, while filtrate is discharged via gravity to the outlet flange.

Versatile Range of Capacities to Suit all STPs

There are currently 4 models in the Huber screw press ranging in capacity to process a dry solids load from 90 kg/hr to 540 kg/hr.

The table below shows the nominal design capacities of the models available.

| Model Number | Max Hydraulic Flow (m3/h) | Max Solids Load (kg/h) |

| Q280 | 2 | 90 |

| Q440.2 | 4 | 180 |

| Q620.2 | 10 | 350 |

| Q800.2 | 20 | 540 |

Flexible Configurations to Meet Every Requirement

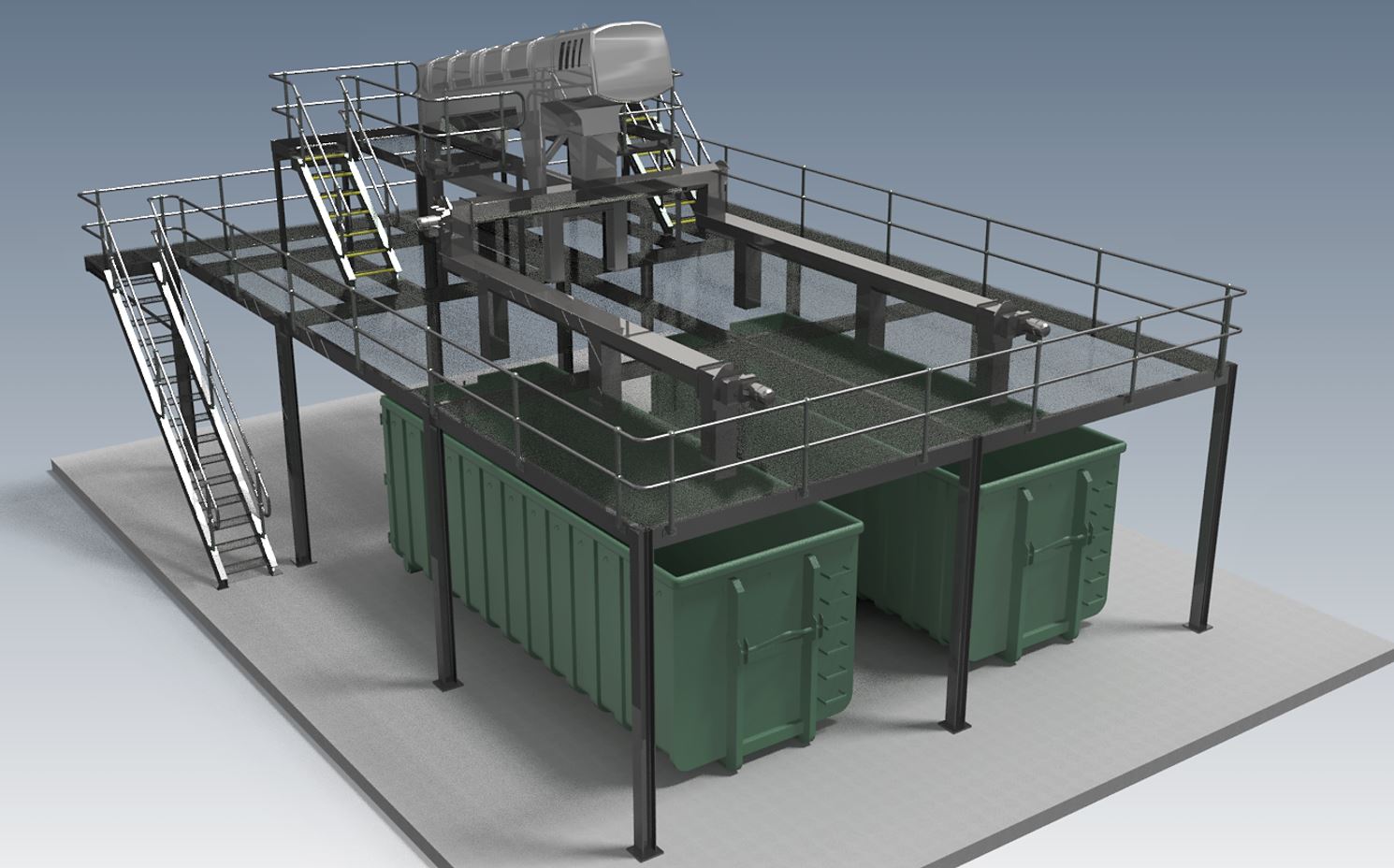

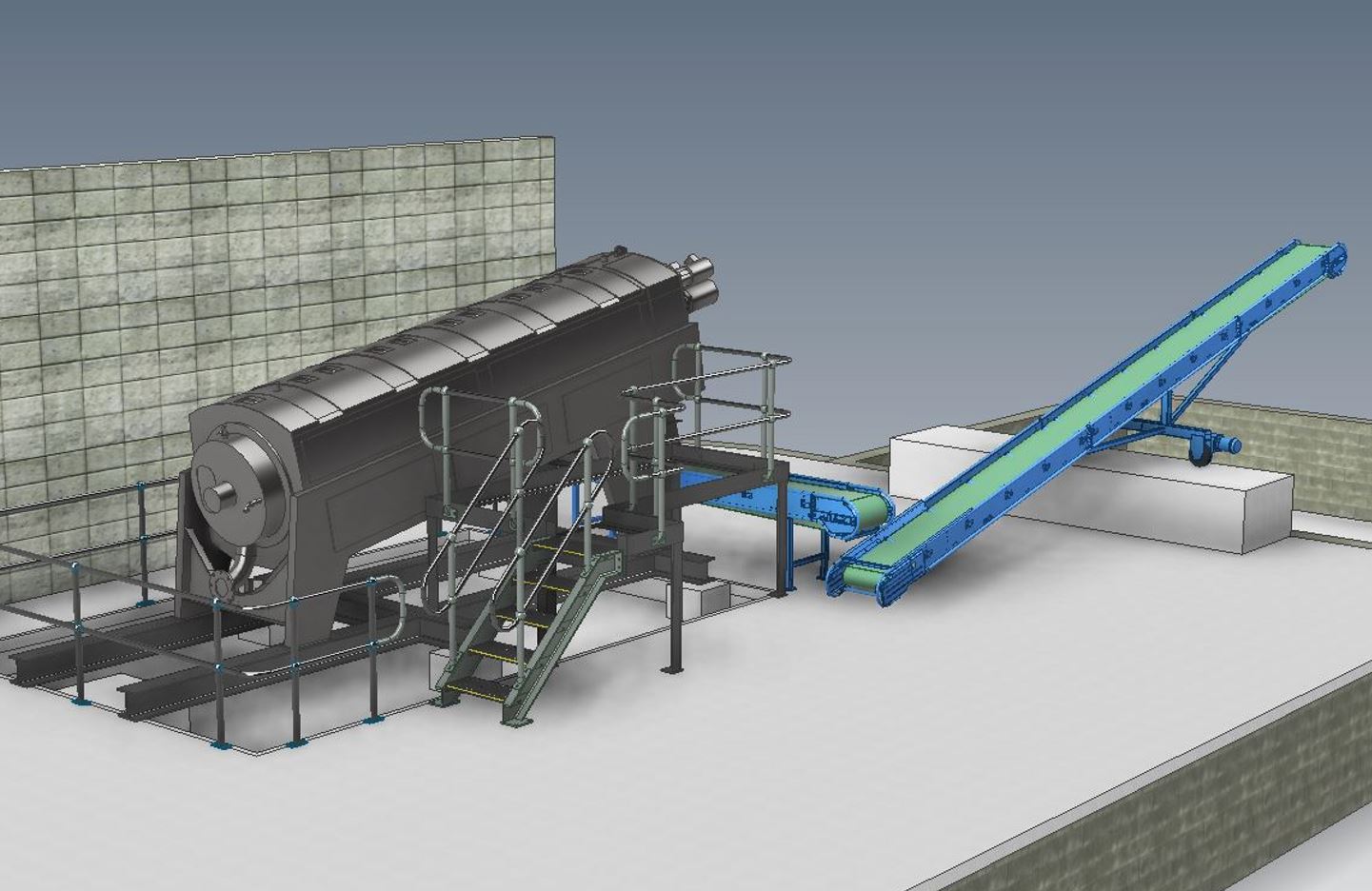

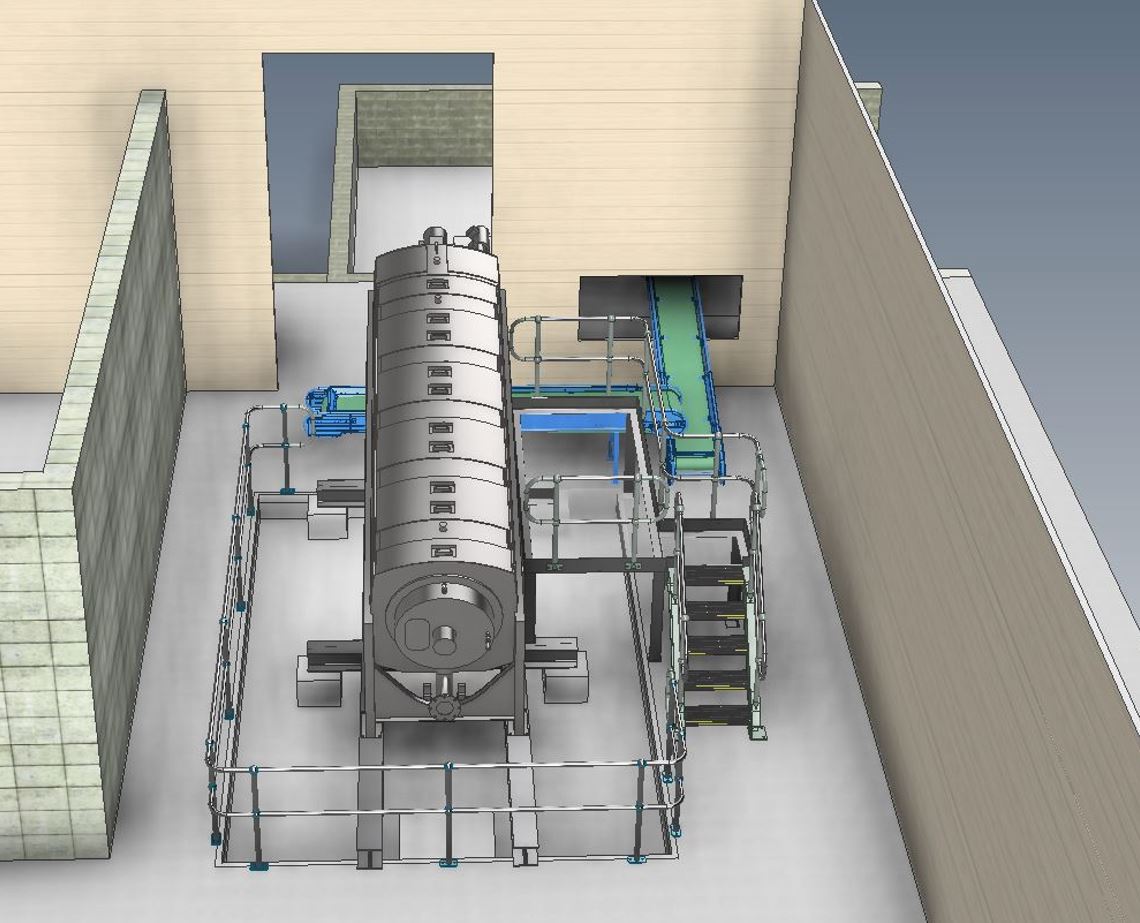

The HUBER Q-PRESS can be configured in multiple ways to suit logistics and dewatered solids removal methods. Key factors influencing the setup include plant layout, available space, sludge volume, and disposal requirements. Dewatered solids can be discharged directly into bins, hoppers, or conveyors, which then transfer the material to trucks, skips, or storage silos for further handling. Each configuration is tailored to maximise operational efficiency and minimise costs. Additionally, containerised unit options are available via Hydroflux Epco’s HySludge®.

Low-Maintenance Design – Minimal Upkeep Required

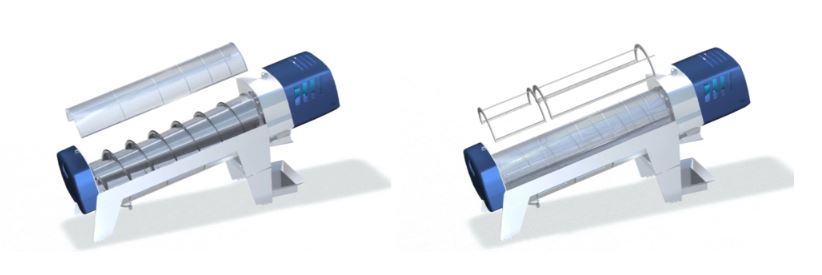

The HUBER Q-PRESS is designed to require minimal maintenance and typically only once every few years access to the internal screw is required. The latest range of larger machines offers a spilt basket to simplify access to the internal components without the need to remove the main screw. The following diagrams show the top half of the basket being removed for screw wiper replacement in situ – a task that is only required every few years.

Regular maintenance primarily consists of basic cleaning, routine oil changes, and lubrication, all of which can be easily performed by local maintenance contractors without the need for specialised technicians. The design of the Huber Screw Press ensures that maintenance access points are easily reachable, simplifying servicing tasks. For plants looking to further streamline maintenance.

Contact Hydroflux Epco to discuss sludge dewatering for your site

Sludge dewatering is a critical step in wastewater treatment, and choosing the right equipment can significantly impact operational efficiency and costs.

With a strong track record of successful Q-PRESS installations, Hydroflux Epco provides unmatched expertise in sludge dewatering system design, commissioning, and optimisation. Our team ensures each solution is tailored to your specific requirements, helping you achieve exceptional dewatering efficiency, energy savings, and long-term performance.

Get in touch with Hydroflux Epco today to find out how we can help streamline your sludge dewatering processes.

Screw Press FAQs

Hydroflux Epco provides a complete end-to-end solution for municipal sludge dewatering projects. Our services cover the full design, supply, and installation of the HUBER Q-PRESS system, including the integration of supporting infrastructure such as conveyors, platforms, and advanced automation.

We work closely with councils, water authorities, and engineering teams to customise the design according to site-specific requirements. Our team ensures the entire process runs smoothly—from initial concept to commissioning—minimising disruptions to ongoing plant operations. Post-installation, we also offer training and ongoing support to help operators maximise the system’s performance and lifespan.

The HUBER Q-PRESS is specifically designed to meet the needs of municipal wastewater treatment plants, providing efficient and reliable sludge dewatering with minimal operational costs. Its slow-rotating screw technology delivers excellent dry solids results while using only a fraction of the energy required by traditional decanter centrifuges—just 10% in most cases. This efficiency translates into significant long-term savings for councils and water authorities.

Additionally, the system operates with minimal noise, no vibration, and is fully enclosed, making it safer and cleaner for both operators and the surrounding environment.

Downloads

Download brochures and technical information on the Huber Screw Press here