Sludge Thickening

Efficient, Reliable, and Cost-Effective Sludge Thickening Solutions

With over 1,000 HUBER thickeners installed worldwide, including many across Australia, these systems have proven their effectiveness in optimising sludge treatment processes. Efficient sludge thickening is essential for successful downstream treatment or dewatering, and the HUBER Rotary Screw Thickener S-DRUM and HUBER Disc Thickener S-DISC deliver exceptional performance with simplicity and reliability.

Please explore a selection of HUBER thickener installations at STPs across Australia in the gallery below.

These compact, fully enclosed systems are designed for low operational costs and minimal operator involvement. The Rotary Screw Thickener can handle sludge flows of up to 80 kL/hr, making it ideal for larger applications, while the Disc Thickener, with a capacity of up to 40 kL/hr, is perfectly suited for smaller-scale operations.

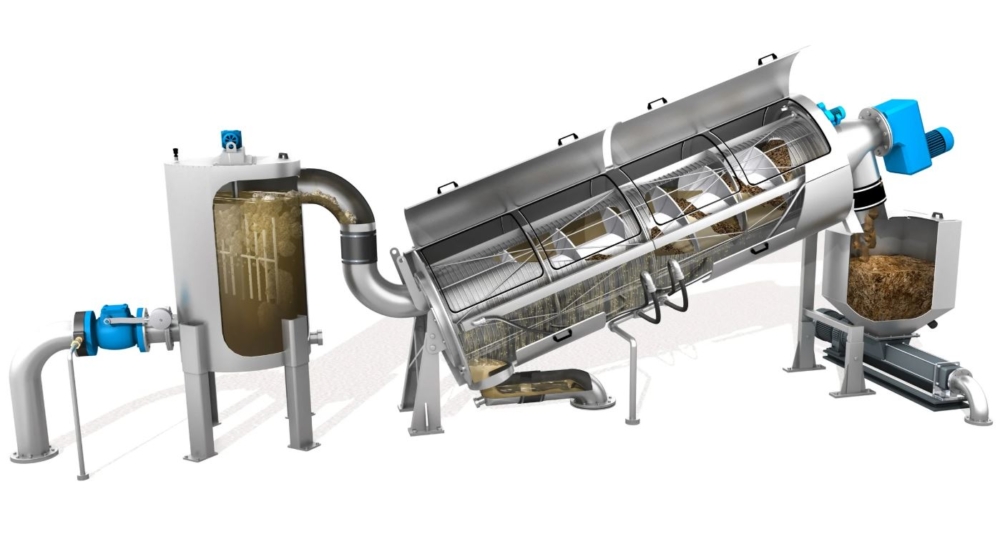

S-DRUM Rotary Screw Thickener

The HUBER S-DRUM Rotary Screw Thickener is a high-performance, energy-efficient solution that achieves over 6% DS with an ultra-low power consumption of just 35 W/m³. Its fully enclosed stainless-steel construction ensures compliance with Australian WHS standards, providing a safe, odour-free, and low-maintenance operation.

Some of the S-DRUM advantages are:

- Sludge volume reduction by up to 80%

- Sturdy design for high solids loads and sludge with coarse materials

- Maximum system availability with a virtually wear-resistant, clog-free stainless steel wedge section basket

- High operational reliability with a slow screw speed

- Low power and water consumption with minimal spray water usage

- No lubrication is required for simplified maintenance

- Completely encapsulated for odour-free operation

- No vibration during the operation

- Low noise levels below 68 dB(A)

Principle of Operation

Flocculated sludge enters the S-DRUM from the thickening tank via gravity. Inside the drum, a slow-rotating screw conveyor evenly distributes the sludge across a wedge wire screen. Water drains through the screen while solids are gradually thickened and conveyed to the discharge point. The enclosed system ensures low odour emissions, minimal maintenance, and long-term reliability.

The S-DRUM is designed for low-maintenance operation, requiring no lubrication and minimal operator intervention. The entire process is fully enclosed, eliminating odours and maintaining a clean, safe working environment.

Capacities and Operational Data

The HUBER Rotary Screw Thickener S-DRUM delivers highly efficient sludge thickening results, with dry solids (DS) content exceeding 7% in typical municipal applications. This performance is achieved with minimal polymer consumption, typically ranging between 3 to 5 g/Kg of sludge. The system is designed to operate with exceptional energy efficiency, consuming only 35 W/m3 of sludge processed.

Water usage is similarly optimised, with a spray water demand of approximately 25 L/m3. The S-DRUM is available in various sizes to accommodate a wide range of operational needs, with throughput capacities ranging from 20 to 100 m3/hr per unit.

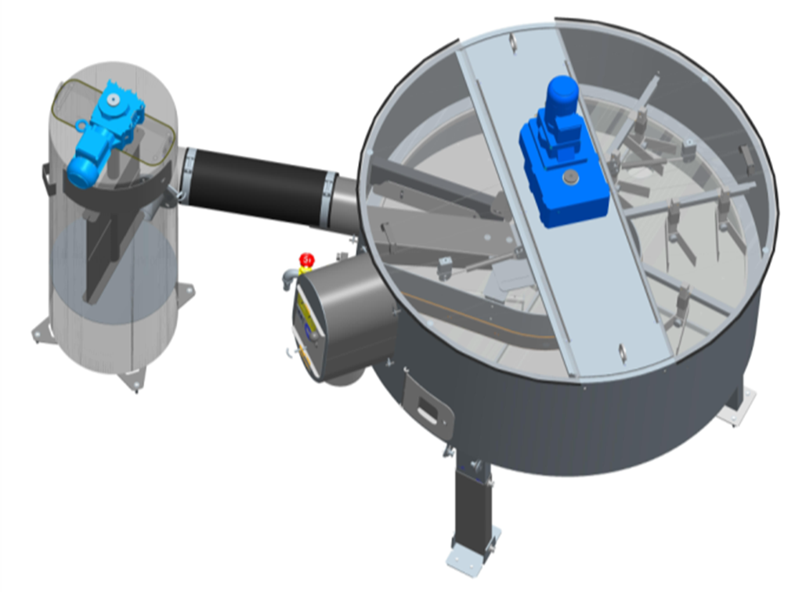

S-DISC Disc Thickener

The HUBER S-DISC Disc Thickener is a compact, cost-effective solution designed for smaller sewage treatment plants, handling up to 40 m³/hr per unit. Like the S-DRUM, it features low energy consumption, minimal maintenance, and fully automated operation, making it an efficient choice for optimising sludge thickening.

Some of the S-DISC advantages are:

- Achieves more than 6% DS in the discharge for optimal sludge thickening

- Low power consumption of just 30 W/m³

- Reduces sludge volume by up to 85%, lowering disposal costs

- Slow filter rotation of < 5 rpm

- Robust design with easy access for inspection, maintenance and operation

- Low Maintenance Requirements, Minimum operator attendance requirements of less than 10 minutes per day

- Fully enclosed design with optional odour ventilation sockets for a cleaner work environment and odour-free operation

With low energy and water consumption, the HUBER S-Disc Thickener provides a reliable, long-term solution for wastewater treatment plants looking to enhance performance in sludge thickening, reduce operational costs, and simplify sludge handling.

Principle of Operation

The HUBER Disc Thickener operates through a simple, efficient filtration process. Flocculated sludge is introduced onto a slightly inclined, slowly rotating filter disc covered with a specialised filter cloth. A baffle plate ensures even distribution of the sludge across the entire surface of the disc for consistent performance.

As the disc rotates, sludge collects in the lower section, creating a low hydrostatic pressure that naturally promotes water drainage through the filter cloth. Flexible ploughs move across the surface, gently shifting the sludge and creating small furrows. This movement allows water to drain more effectively, enhancing the filtration process. At the discharge end, a scraper removes the thickened sludge from the disc.

A spray bar automatically cleans the filter cloth by washing the retained solids back into the sludge stream, ensuring the filtrate water remains clear and the system continues to operate efficiently.

Capacities and Operational Data

The HUBER Disc Thickener offers exceptional sludge thickening performance, achieving volume reductions of over 85% and dry solids content exceeding 6%. It operates with low polymer consumption and energy use, requiring less than 0.03 kWh per cubic metre.

The system is highly efficient, needing less than 10 minutes of operator attention per day. Wash water demand is minimal, at less than 5% of sludge throughput, with the option to use filtrate water for cleaning. With a separation efficiency of over 97%, the Disc Thickener provides a reliable, cost-effective solution for sludge treatment.

Two standard units are available, Size 1 has a capacity of 20 m3/hr and Size 2 has a capacity of 40 m3/hr.

Optimise your Sludge Thickening Process with Hydroflux Epco

The HUBER S-DISC and S-DRUM thickeners provide efficient, reliable, and cost-effective sludge thickening solutions for municipal and industrial wastewater treatment plants.

The HUBER S-DISC Disc Thickener is ideal for smaller plants, with capacities of up to 40 m³ per hour. Its compact, fully enclosed design ensures odour-free operation, while low energy and water consumption help reduce operational costs. The system requires minimal operator involvement, making it a convenient and efficient choice for sludge thickening.

The HUBER S-DRUM Rotary Screw Thickener is perfect for larger applications, handling sludge flows of up to 80 m³ per hour. It delivers exceptional thickening performance with dry solids content exceeding 7%, using only 35 W/m³ of power. Its robust stainless steel construction, low-speed screw operation, and wear-resistant components ensure long-lasting, reliable performance.

Get in touch with Hydroflux Epco today to learn how we can help streamline your wastewater treatment operations with reliable, high-performance solutions.

Frequently asked questions

The S-DISC and S-DRUM are designed for minimal operator involvement, requiring less than 10 minutes of attention per day.

The advanced control systems can automatically adjust throughput, polymer dosage, and rotation speed to maintain consistent, high-quality thickening results. This automation helps reduce labour costs and operational complexities, making the process more efficient and user-friendly.

Yes, both the S-DISC and S-DRUM are designed to handle a wide range of sludge characteristics. Their automated control systems can adapt to fluctuations in sludge consistency, solids content, and flow rates.

The sturdy stainless steel construction and flexible internal components ensure reliable operation even when dealing with high solids loads or sludge containing coarse materials, making these systems suitable for a variety of wastewater treatment applications.

Both systems are exceptionally energy- and water-efficient. The S-DRUM consumes just 35 W/m³, while the S-DISC uses less than 0.03 kWh/m³, significantly reducing operational costs. Water consumption is also kept to a minimum, with wash water demand typically below 5% of sludge throughput. For added efficiency, filtrate water can be reused for cleaning the spray bar, reducing overall water use and promoting more sustainable wastewater treatment practices.

Downloads

Download the HUBER Sludge thickening brochures here