HyDAF Dissolved Air Flotation

Dissolved Air Flotation (DAF) Systems – Designed and Fabricated in Australia

Hydroflux Epco offers a unique and comprehensive range of Dissolved Air Flotation (DAF) units, designed and fabricated in Australia. The Hydroflux HyDAF systems are engineered for high efficiency, delivering reliable and consistent performance across a wide range of water and wastewater treatment applications.

With over 200 systems in operation globally, Hydroflux HyDAF systems are available in various configurations, ensuring flexibility to meet specific operational requirements. These systems can handle capacities exceeding 300 kL/hr as standalone units, making them suitable for both small-scale and large-scale operations.

Municipal Applications for the Dissolved Air Flotation

Dissolved Air Flotation (DAF) is widely used in municipal water and wastewater treatment for various applications, including:

Drinking Water Treatment – Dissolved Air Flotation is used in water treatment plants to remove algae, turbidity, natural organic matter, and colour, particularly in surface water sources with high suspended solids.

Primary Wastewater Treatment – In municipal wastewater treatment, Dissolved Air Flotation is used as a primary clarification step to remove suspended solids, fats, oils, and grease (FOG) before biological treatment.

Tertiary Treatment and Phosphorus Removal – Dissolved Air Flotation can be used for tertiary clarification, particularly for algae and phosphorus removal when combined with chemical coagulants, helping municipalities meet stringent discharge limits.

Sludge Thickening – Dissolved Air Flotation is effective in thickening waste-activated sludge (WAS) before digestion or dewatering, reducing the volume of sludge for further processing.

What Makes the HyDAF Unique

The HyDAF Dissolved Air Flotation system is a high-quality engineered system designed to efficiently and effectively remove solids from water and wastewater streams. For every application, the HyDAF is scientifically modelled to ensure that when put into operation, it will meet and exceed all performance and operational expectations.

Optimised Flotation Engineering

A well-engineered Dissolved Air Flotation system requires the combination of a robust flotation tank with a suitable solids removal mechanism and an efficient and effective dissolved air production and injection system.

The HyDAF system comprises a specially designed inlet mixing system that provides a suitable amount of shear and turbulence where the dissolved air is injected and mixed with the water stream, which enhances microbubble attachment and offers improved performance.

The following set of videos shows the Hydroflux modelling process with varying dissolved air stream flows and pressures.

Settled Sludge Removal to Suit All Applications

Hydroflux has three flotation tank configurations available to suit all types of influent streams.

HD Range: effective when minimal settled solids are expected, and the entire DAF can be easily drained when required.

HD-V Range: designed for wastewater streams with a high probability of sedimentation. This unit is fitted with steep sloping sides and a screw conveyor that automatically extracts settled solids.

HD-S range: designed for large DAF systems with multiple hoppers to facilitate automated withdrawal of solids on a regular basis.

The Perfect Way to Create and Introduce Dissolved Air

Ensuring that the correct amount of dissolved air is injected into the DAF inlet is essential for the performance of the system.

Hydroflux Epco utilises a proprietary proven engineering design tool to ensure that the dissolved air system is appropriately sized for every application. The engineering tool takes into account the influent flow rate, solids load, temperature and operating pressure.

Features of the recycling system include:

- Stainless steel saturation vessel that contains no internal instruments or components

- Non-blocking design with stainless steel closed impeller high-efficiency pump and self-cleaning pressure reduction valve

- Integrated air control panel enabling accurate adjustment of airflow

- Proven design in hundreds of installations

Design and Construction Capabilities

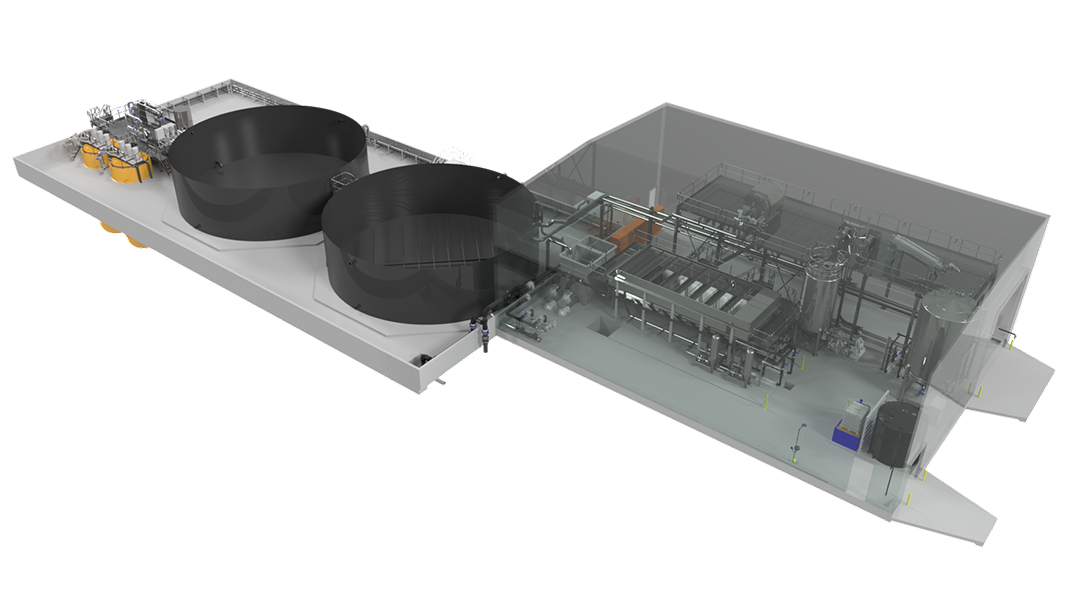

The HyDAF dissolved air flotation system is just one process component in a complete water or wastewater treatment plant and is usually supported by a range of ancillary process operations to condition the influent, handle the sludge generated, or provide further treatment or recycling. Hydroflux Epco has the skills and expertise to conduct any design and construct project incorporating a DAF system. Hydroflux Epco employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices throughout Australia, providing a local presence throughout the project.

The drawing above shows a Hydroflux treatment plant incorporating Dissolved Air Flotation, screening and sludge management.

Contact Hydroflux Epco for an initial technical discussion

Our team of experts understands the complexities of applying dissolved air flotation to water and wastewater treatment plants and will always provide tailored advice on selecting, designing, and optimising the correct screening dissolved air flotation system in each case.

Get in touch with Hydroflux Epco today to learn how we can help streamline your operations with reliable, high-performance Dissolved Air Flotation systems.

Downloads

Download a brochure and technical information on HyDAF here