RoadTrain® Secures Discharge for OK Tedi at Wangbin, PNG

EPCO Australia has a long history in providing packaged sewage treatment solutions called RoadTrain® to clients in PNG, with over 30 installations in that market.

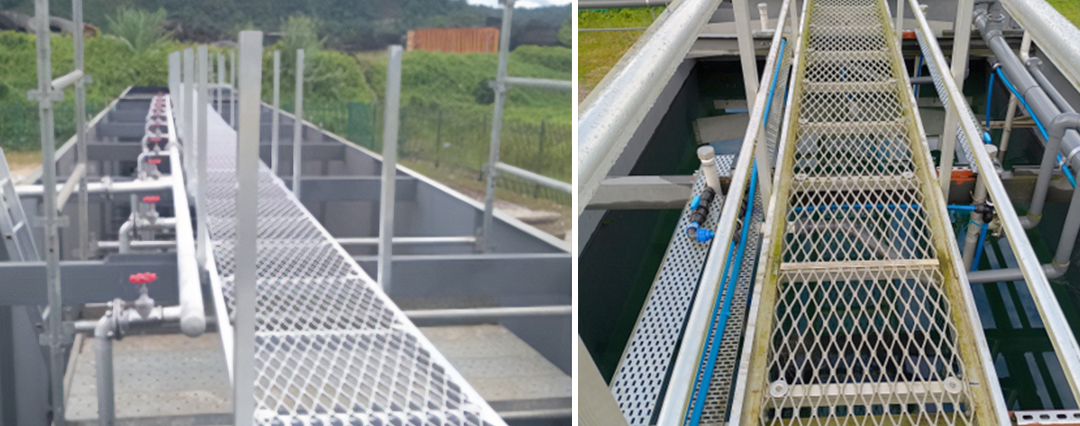

The first RoadTrain® in Wangbin was installed in 1982 as part of the original mine construction project. A second similar system was installed in 2023 to meet the growth of the community once again demonstrating easy scalability for sites where there is a capacity augmentation.

The RoadTrain® welded package plant system included,

- Inflow splitter

- Aeration tank

- Settling (Clarifier) tank

- Chlorine tank

All the raw sewage flows into the influent sump from where it is then pumped through a static screen and is divided by a flow splitter to evenly split the flow going towards each Roadtrain®.

The plat is based on the intermittent aeration treatment process. The intermittent aeration tank (IAT) receives the mixed liquor from the inlet and return activated sludge (RAS) from the secondary clarifier. The tank is intermittently aerated, with air provided by blowers provided in duty/standby mode. The blower start-up and shutdown are controlled via times which allows the generation of anoxic and aerobic conditions within a single process tank similar to the function of an SBR process.

The mixed liquor from the aeration tank flows into the clarifier via an energy dissipating inlet and an inlet baffle that helps reduce the amount of mixing and turbulence introduced into the tank. The still nature of the tank allows for the gravity sedimentation of the activated sludge solids present in the mixed liquor, which creates a concentrated sludge stream from the base of the unit, and a clarified water stream from the top.

Clear water overflows a final effluent weir, consisting of a knife-edged weir, and discharges to the effluent outfall via a chlorinator system. A scum deflector baffle and skimmer protect the final effluent weir from any accumulated surface scum, with scum being returned via airlift to the IAT for re-processing.

| Item | Value |

| Capacity | 500 EP |

| Process | Extended Aeration |

| Flow | 100 m3/d |

| Design Configuration | Welded Tank |

| Year | 2023 |

Effluent discharges from the secondary clarifier and passes through the tablet chlorinator. Within the chlorinator the effluent is contacted with solid calcium hypochlorite, which dissolves, releasing chlorine into the water which kills bacteria present, disinfecting the final effluent before it discharges to the outfall.