Biogas Equipment

Hydroflux can supply a range of biogas treatment systems that are engineered to maximise the recovery and utilisation and will typically comprise:

- Biogas Flares

- Biogas Storage

- Biogas Blowers

- Biogas Chilling & Biogas Skids

- Biogas Scrubbing

- Digester Systems

Find out more

Biogas Flares

A biogas flare is always installed to allow biogas to be safely burned off whether biogas is not being re-used, to avoid release of the methane rich biogas to the environment.

Methane is a powerful greenhouse gas and according to the UN environment programme, it is 80 times more potent over a 20-year period to global warming than CO2. Safely combusting the methane converts the CH4 in the biogas to CO2 which reduces the reduces not only the green house potential but also odour emissions and release of H2S.

A typical MTU series flare with concealed combustion and insulated combustion chamber for safe and efficient combustion of biogas

Biogas Storage

Intermediate storage of biogas is commonly required to buffer the produced biogas before using it in the boiler or CHP. This is usually needed to even out the flow rates between biogas produced and biogas used in the combustion device.

Hydroflux can offer gas storage solutions in various configurations and sizes to suit your needs.

The outer membrane forms the actual protective construction and is supported with air pressure. The actual gas holder is in the inner membrane. This inner membrane moves up or downwards depending on the filling level.

Dry gas storage with gas storage membranes inside fixed structures

Biogas Blowers

Himmel GVD Biogas blowers, available for flow rates from 50 to 6000m3/h.

Biogas blowers will typically be required to transfer biogas from the covered anaerobic lagoon at a controlled rate and pressure to downstream equipment. The specialised Himmel GVD Biogas blower, designed for operation with wet biogas and several other options are available to suit your application.

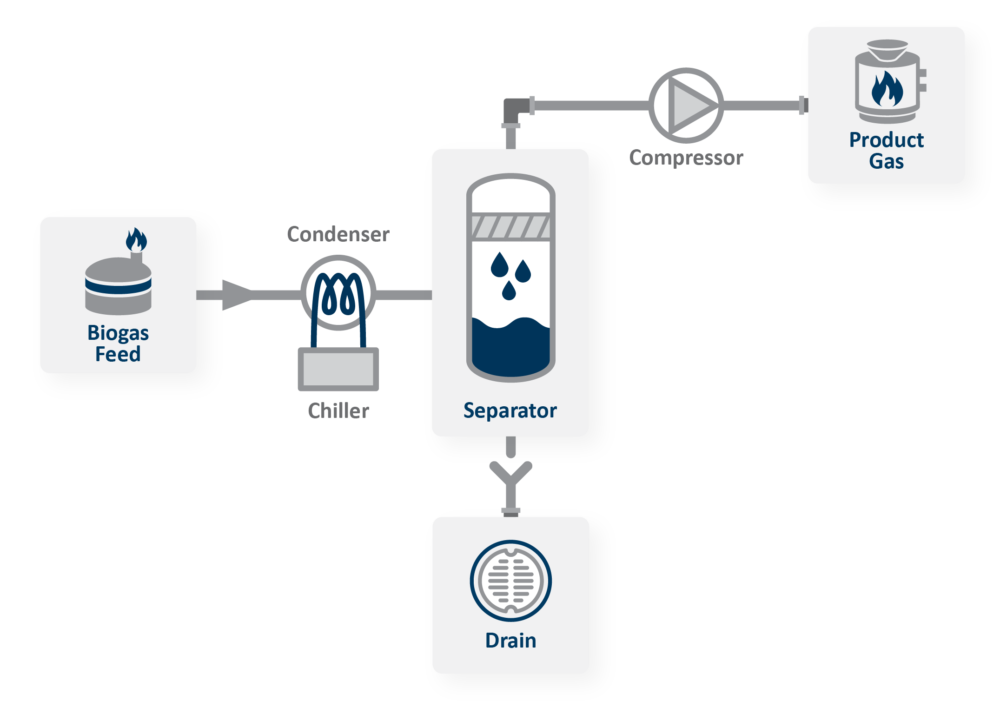

Biogas Chilling (Moisture removal) and Biogas Skids (Moisture removal and gas pressure boosting)

Digester produced biogas is 100% water saturated and as it cools in the lines to the point of reuse, large amounts of water can condense in the piping system and the combustion device.

There are multiple benefits in drying biogas to a low dew point before combustion in a combined heat and power (CHP) engine or boiler. Hydroflux can incorporate the most suitable biogas cooling and collection system into the treatment process. These can be offered with or without compressors for gas pressure boosting.

The benefits of cooling (drying) to a low dewpoint are:

- Increased engine/boiler efficiency

- Prevention of corrosion/oil contamination

- Partial removal of impurities such as H2S, ammonia and siloxanes

- Complying with technical instruction of gas engine/boiler suppliers

Biogas Scrubbing (Desulphurisation)

Typical Bioscrubber unit for H2S removal

Removal of hydrogen sulphide and moisture from biogas is essential to avoid rapid corrosion to equipment such as CHP generators and benefits the longevity of other equipment such as biogas boilers.

Hydroflux offer a range of biochemical, media or biological gas scrubbers that will ensure that the biogas is suitably conditioned for use in your combustion device.

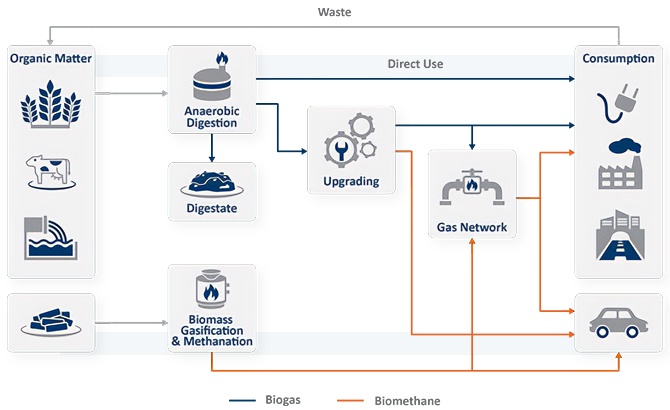

Biomethane upgrading

The Bioenergy Roadmap by the Australian Government has identified that up to 23% of the total gas used in Australia could be derived from Biomethane by upgrading Biogas to quality requirements for Natural Gas and injecting it into the national gas grid.

The technology for Biomethane upgrading is mature and proven in installations worldwide for over a decade.

Hydroflux can assist with identifying and offering solutions to suit your requirements.