Polishing Screens

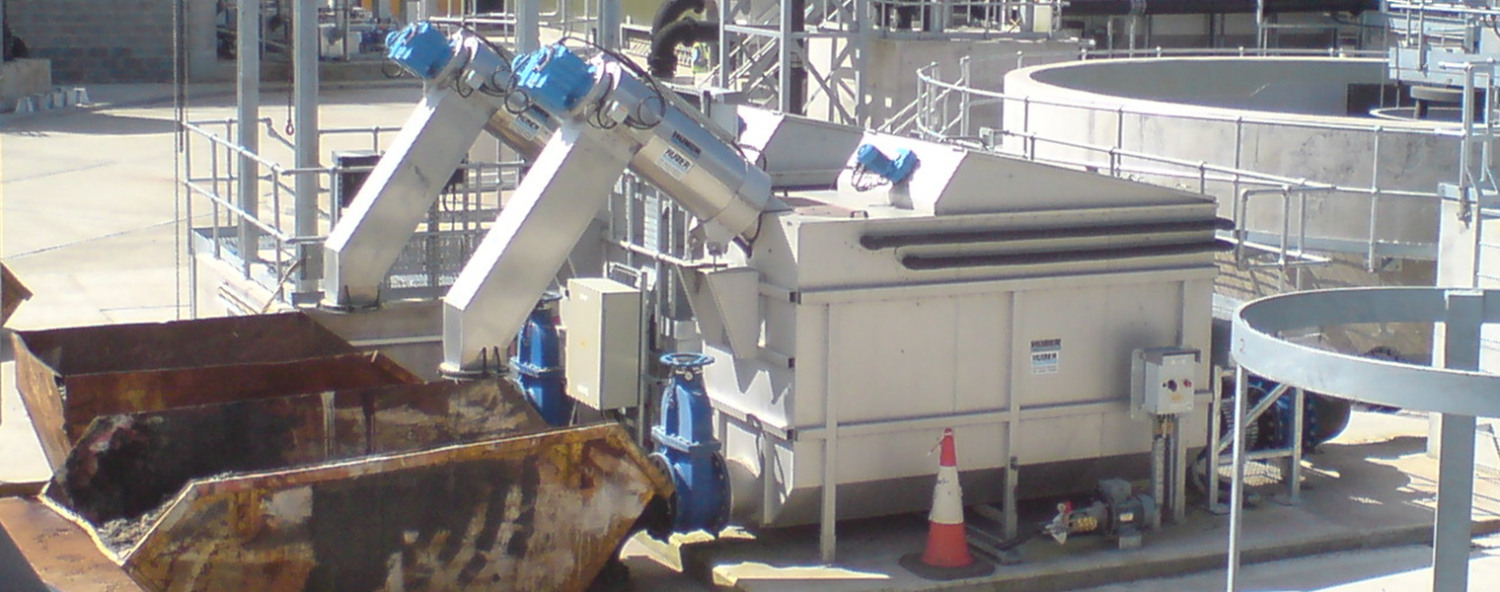

The HUBER RoMEM Screens is one of the range of high quality German manufactured screens that has been designed specifically for pre-MBR screening. Over 100 RoMEM screens are operational worldwide in large scale MBR plants protecting both flat sheet and hollow fibre membranes.

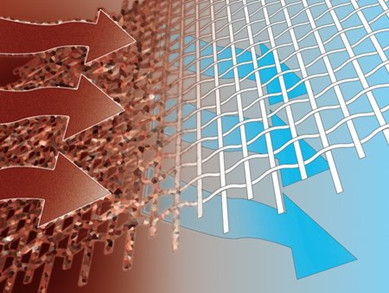

Separation of fibrous material is important prior to any membrane plants as fibres may lead to tressing or blocking of the membrane with the result of a reduced membrane permeability and poor membrane plant performance.

The RoMEM is the ideal solution for membrane protection and is designed specifically with a low head loss and excellent separation of fibres. The screen can be supplied as either a square mesh or perforated plate design

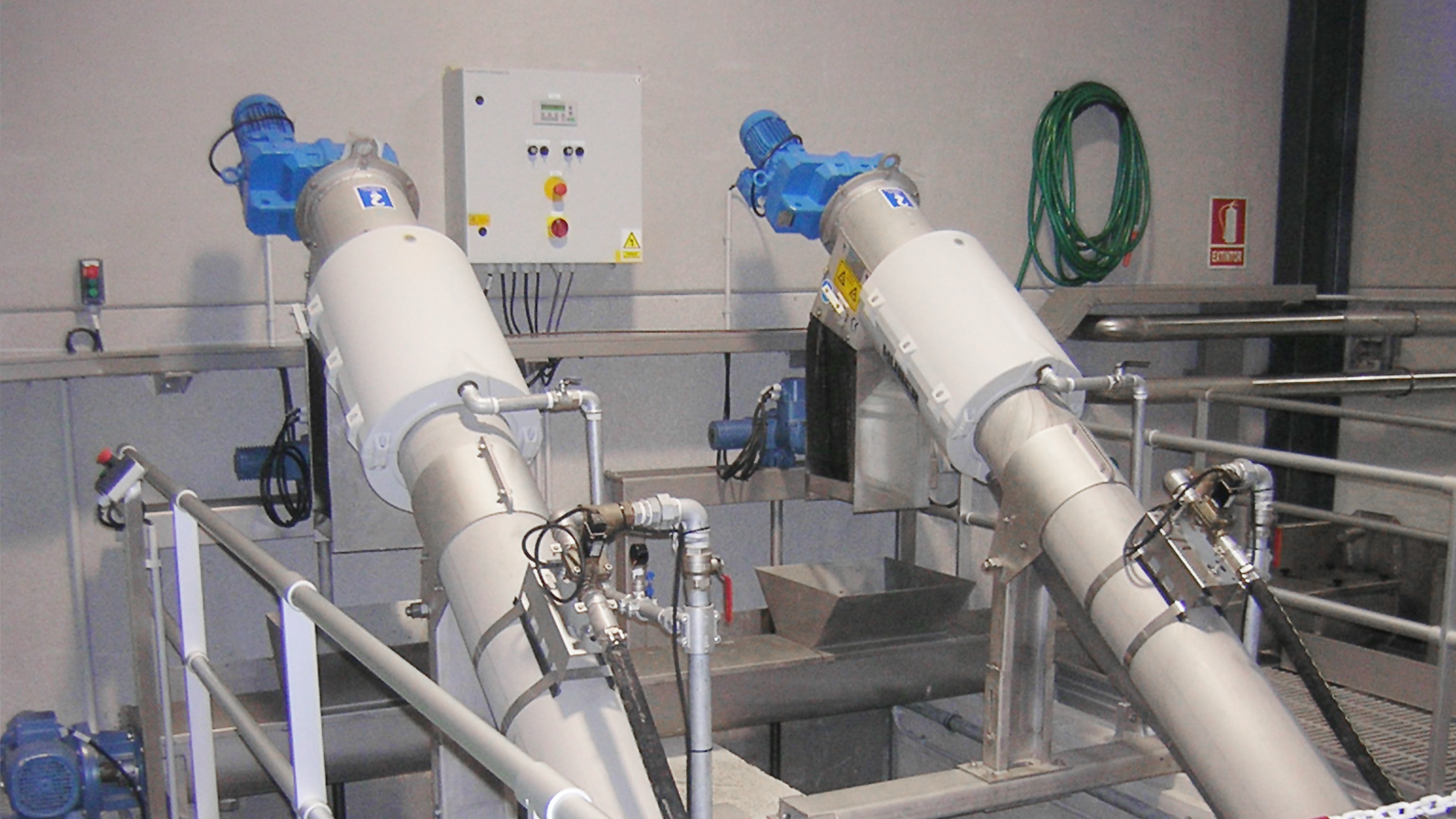

The ROTAMAT® RoMEM can be supplied with screen basket diameters from 780 to 3000 mm allowing flows of up to 3500 m³/h depending on the mesh sizes which can be from 0.5 to 1.0 mm.

Find out more

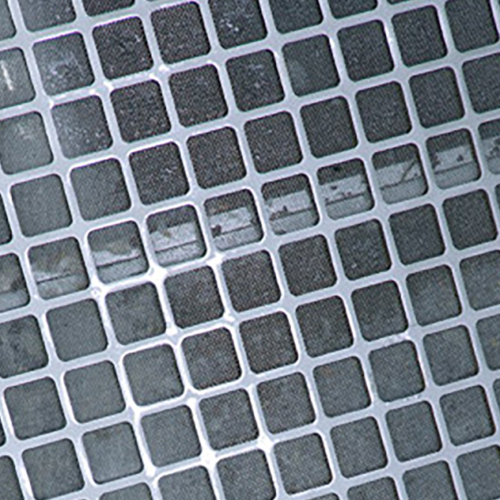

The ROTAMAT® Membrane Screen is a very fine screen with a low headloss and provides a large screening surface due to its drum-shaped screen basket and 35° installation angle. The screen uses a square mesh that provides, contrary to conventional slot screens, a defined separation size and therefore ensures reliable separation of solids.

The ROTAMAT® Membrane Screen is a very fine screen with a low headloss and provides a large screening surface due to its drum-shaped screen basket and 35° installation angle. The screen uses a square mesh that provides, contrary to conventional slot screens, a defined separation size and therefore ensures reliable separation of solids.

The two-dimensional design and very fine apertures especially prevents fibres and hairs being washed through the mesh before the screen basket surface is cleaned. Slot screens are not able to achieve the same efficiency due to their undefined separation size. In addition, square meshes have a very large free surface and are therefore able to cope with high hydraulic capacities despite their fine mesh.

The ROTAMAT® Membrane Screen is suitable for municipal and industrial wastewater flows of up to 3500 m³/h and can be equipped with a square mesh size from 0.5 to 1.0 mm.

The low space requirement and high efficiency through a complete treatment by the combination of screening, transport, compaction, dewatering and discharge in one compact unit make the ROTAMAT® Membrane Screen an efficient and economical solution for removal of high solids concentrations. The screen can be installed either directly into a channel or a separate tank.

The waste water flows through the open front into the screen basket and through the very fine apertures of the mesh. A sealing plate between the channel and the frontend screen basket opening prevents unscreened wastewater from bypassing the screen basket. The solids can therefore not pass into the effluent but are reliably retained in the screen basket.

The screen basket surface consists of a square mesh that ensures high separation efficiency and provides a large free screen surface so that the head loss remains low even with high flow rates.

The solids retained on the screen basket surface lead to gradual blinding of the basket surface which has an impact on the level difference in the channel. The screen basket cleaning cycle starts at a defined water level in the channel upstream of the screen. The blinded screen basket surface is cleaned as the screen basket rotates lifting the retained solids to the spray water cleaning system where they are washed into the trough in the centre of the screen basket. The screenings are removed from the trough by a screw conveyor and dewatered and compacted as they are transported upwards through a rising pipe.

Periodic high-pressure washing at 120 bar (standard setting is twice a day) eliminates sedimentation on the screen basket and ensures that grease and oil is removed which might clog the screen basket surface.

Hydroflux Industrial supply a comprehensive range of equipment and process including

- Most experienced pre-MBR screening specialists

- Thorough understanding of blinding factors and hydraulics

- Proven technology in this field

- Variety of sizes available up to 3500m3 per hour

- Full stainless steel construction

- Tank mounted versions available