Rotating Bio Contactors

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

RoadTrain® packaged plants can be designed using continuous activated sludge process and configured for nutrient removal if tighter discharge limits are required.

RoadTrain® has been installed in over 150 sites around the world, and is well suited to remote locations where a high level of both process and mechanical robustness is required.

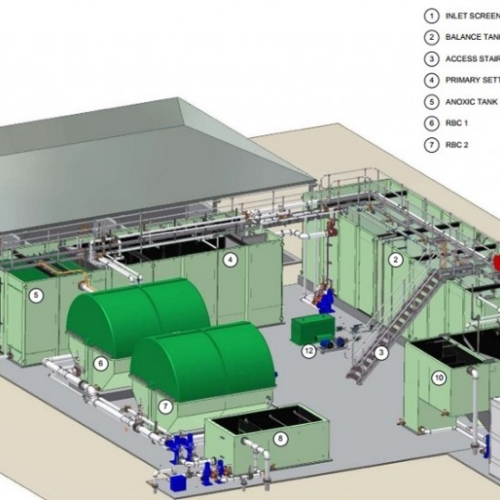

Typically this design would include:

- Primary sedimentation

- Anoxic zone

- Rotating Biological Contactor (RBC)

- Secondary clarification

- Disinfection

- Sludge management

Find out more

- Simple process operation

- Robust heavy duty construction

- Low operating costs due to the use of rotating biological contactor

- Ideal for sites with minimal and infrequent operational support

- High discharge limits can be achieved

- From 60 to 1000EP in a single train

- BOD < 15 mg/L

- TSS < 10 mg/L

- TN < 30 mg/L or < 10 mg/L for tight discharges

- TP < 10 mg/L or 1 mg/L for tight discharges