Strainpress Sludge Screens

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

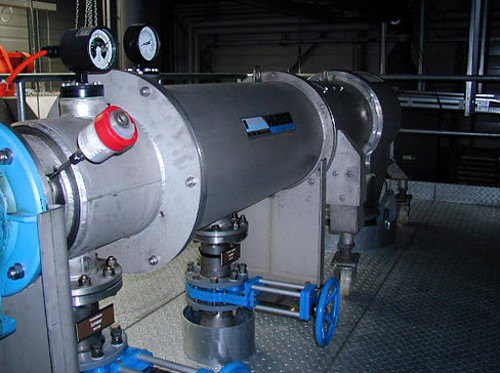

The strainpress sludge screen is a pressure-fed inline system for screening any type of sludge, including highly viscous and greasy waste.

Efficient and reliable sludge screens for removal of disturbing solids (e.g. plastics, hair and fibres) are necessary to prevent disruption of subsequent sludge treatment processes and equipment.

The strainpress Increases the operating reliability of downstream sludge treatment systems, such as thickening, disinfection, stabilisation, dewatering, drying, and reduces maintenance requirements. More than 1000 successful installations worldwide.

The systems have a capacity of up to 110 m3/h of sludge and up to 150 m3/h process water using perforations of 0.15 to 10 mm and the resultant screening will be dewatered to up to 45% DS.

Find out more

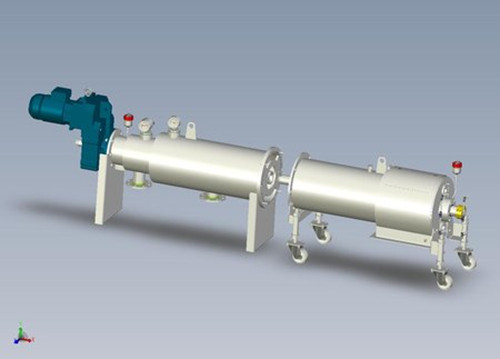

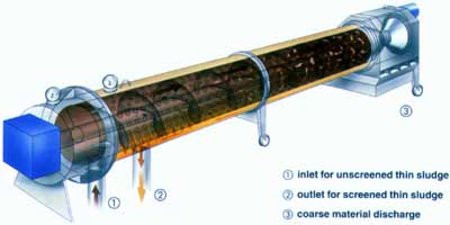

The STRAINPRESS® is a horizontal pipe-shaped coarse material separator which consists of inlet and screening zone, press zone, and a discharge section.

A pump presses the liquid through the screening zone and delivers it to further process steps or utilisation. The liquid is under pressure. The coarse material which is retained on the screen surface is stripped off by a coaxial screw and pushed through the press zone where the material is extensively dewatered and compacted. The compacted material is pressed through a gap around a hydraulically operated pressure cone which closes part of the pipe end and builds up counter pressure.

The system does not need any wash water as backwashing of the screen is unnecessary. The perforation and design of the discharge section are individually adjusted to optimally suit specific requirements. The below diagram shows the installation of the STRAINPRESS® within the wastewater treatment plant. The flow is under pressure as it streams through the STRAINPRESS®, It is therefore easily possible to integrate the STRAINPRESS® into the existing pipeline and automatic system.

- Protect digesters by removal of fine fibre and screenings

- Increase digester efficiency

- Lower maintenance on heat exchangers and recirculation pumps

- The STRAINPRESS®-system can be integrated in a closed pipeline system

- Continuous coarse material separation under pressure with a loss of pressure between 0.4 and 0.6 bar

- Screening, dewatering and transport of the coarse material in one operation

- Washing off sludge or backwashing is not necessary

- Fully-automatic continuous or intermittent operation

- Compact design

- Self adjusting against varying feed solids

The STRAINPRESS® can be used in a variety of applications including

- primary sludge

- secondary sludge

- mixed sludge

- septic sludge

- floating sludge

- grease sludge

- digested sludge

- production wastewater and industrial sludges

- circulation and process water